6 Processes for a Powder Screener

Used in Powder Processing Industries

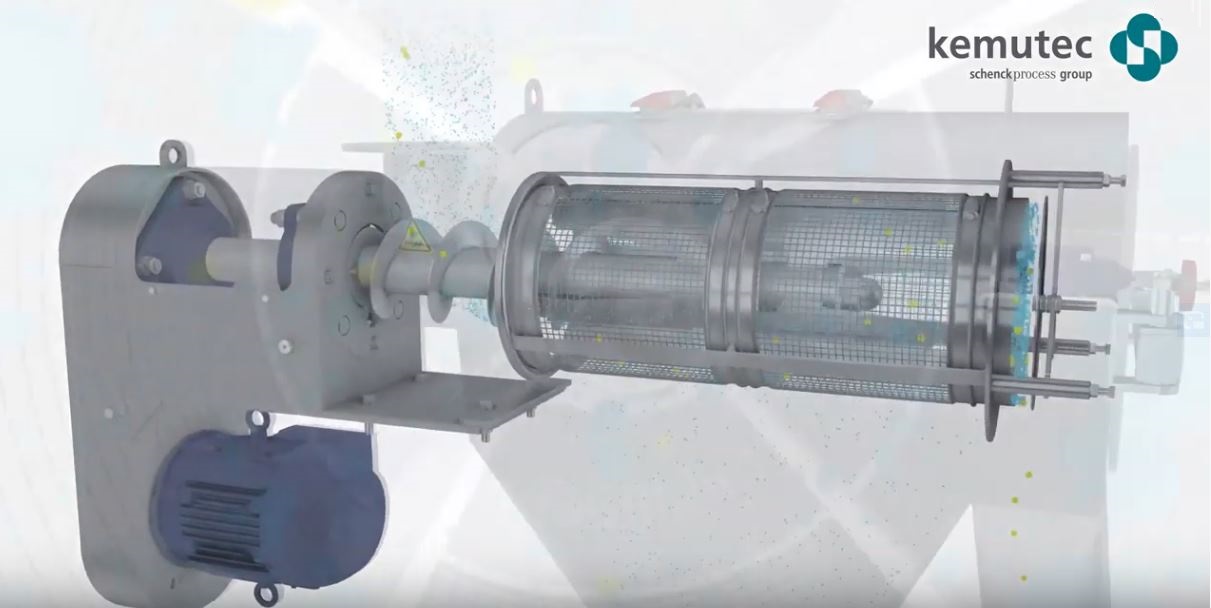

A Powder Screener or what is also known as a Centrifugal Sifter, is an important processing machine for check sieving, whereby particles of different sizes or contaminants are removed from the material. Powder Screeners are also used for size reduction; processing particles into a consistent distribution size. They are commonly used in the Food, Pharmaceutical and Chemical industries.

A Powder Screener operates by separating or breaking up the particles using it’s centrifugal force and the sifter’s screen. Materials used for screens include Nylon Mesh, Steel Mesh, Wedge Wire, Perforated Plate and Special Polymers. The objective for screening and sifting material can be categorised into 6 reasons:

Check Sieving / Policing

Check sifting of bulk materials and powders removes un-wanted material such as string, packaging, plastic, insects and other unwanted items, or hard lumps of agglomerated product before further production.

Scalping

Scaling helps prevent waste or protects packaging equipment, by removing potential quantities of oversize that exceed the maximum feedstock specifications.

Classification

Classification and separation takes places within a stream of product, into two channels. The classification takes place within a range of screen apertures depending on the screen’s size and often occurs before further production/handling takes place.

De-Dusting

De-dusting involves the removal of fines that have been generated through the sifting process, and would otherwise spoil the appearance of a packaged product or cause a problem during future processing.

Conditioning

Centrifugal Screening Sifters are an excellent method to rejuvenate stored product to give it a more uniform density, to make it flow easier.

De-Agglomerating

The use of Centrifugal Sifters ensures that perfectly good material that has agglomerated, are all but the hardest, recovered.

Common Applications for Sifters Include:

Food Processing

- Flour sifting

- Ingredient check sieving

- Dairy powder sieving

- Bakery mix de-lumping and final dressing

- Pet food extruder protection

Chemical Processing

- Fine powder classification

- Nylon flock deagglomeration

- Powder deagglomeration

- Powder paint check sieving

Pharmaceutical Processing

- Check sieving of bulk pharmaceuticals

- Classification of active pharmaceutical ingredients

LEARN MORE INFORMATION ON THE KEMUTEC SIFTER, BY CLICKING HERE >>

Call / email us for a quote or support, or complete our on-line form >>

+44 (0)1625 412000

For USA customer contact support, please go to >> https://www.kemutecusa.com/contact-us/